These are the standard moulded or custom made Expansion Joints consisting of high quality rubber body incorporating floating flanges.

Rubber bellows: Reinforced EPDM, EPDM HT, Nitrile, Spec. Nitrile, Nitrile white, Hypalon, SBR, Viton®, Chloroprene, etc.

Flanges: Zinc plated carbon steel as standard. Also, available in hot dip galvanized carbon steel, stainless steel, etc. drilled to EN and ANSI standards. On request, flanges are also available drilled to JIS and AWWA standards.

For vacuum applications, an internal stainless steel vacuum ring is incorporated.

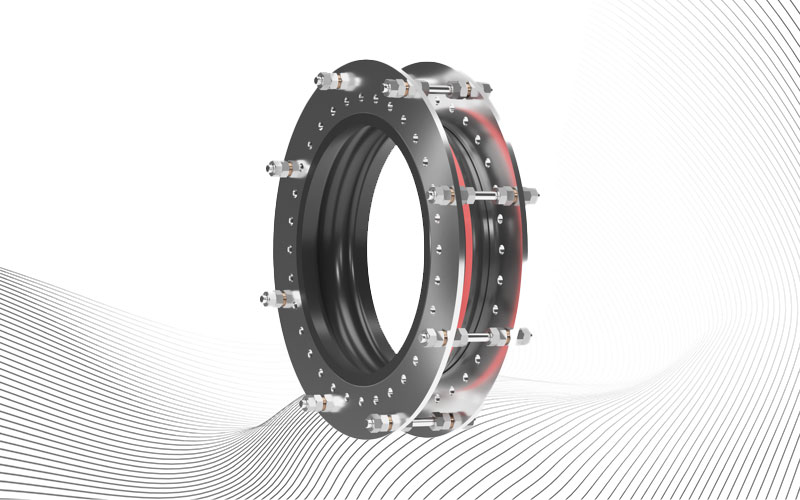

Standard Moulded

Single Arch Rotating Flange

Incorporating control units/tie rod system. A control unit assembly is a system of 2 or more control rods placed across the expansion joint from flange to flange to set the maximum allowable expansion/contraction of the expansion joint and that will contain the pressure thrust. Recommended on most applications to prevent damage due to excessive pipe movements, each rod incorporates double nuts on each end to keep the expansion joint from over- elongating and spherical washers to allow Lateral, Angular and some Torsional movements as well as to accommodate moderate piping misalignments.

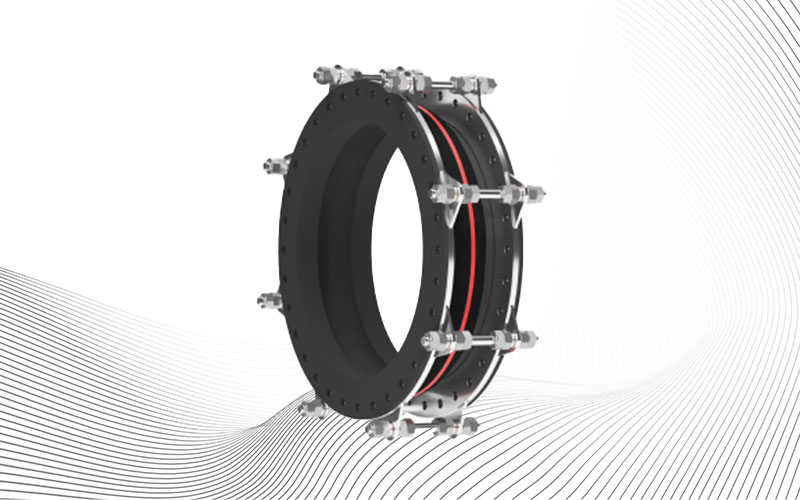

Full Face Rubber Flange

Full Face Expansion Joint

Expansion joints expand in length when under pressure. The force created by this pressure is designated as Pressure thrust. Where the pipe supports and anchors are not designed to absorb this force, tie rods across the joint must be incorporated. Tie rods are designed to take the full pressure thrust and tie rods supports are integrated in the flanges (retaining rings) so there is no thrust on counter flanges.

Recommended on most applications to prevent damage due to excessive pipe movements, each rod incorporates double nuts on each end to keep the expansion joint from over elongating and spherical washers to allow lateral and some angular

movements (2 tie rods only).